Customer Support and Manufacturing Facilities

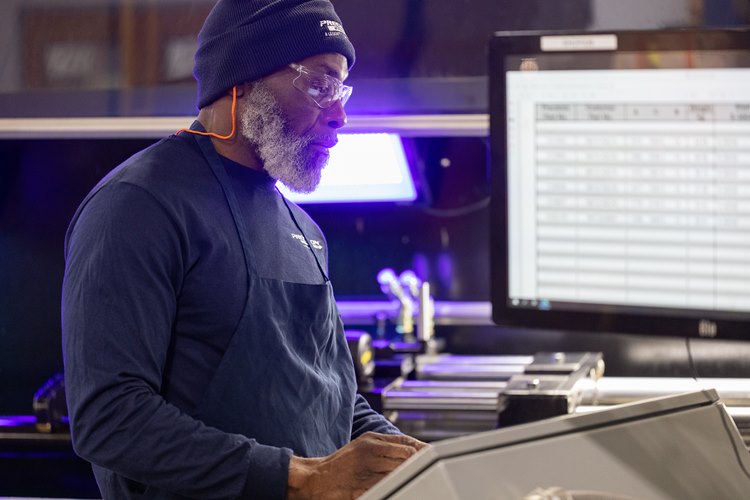

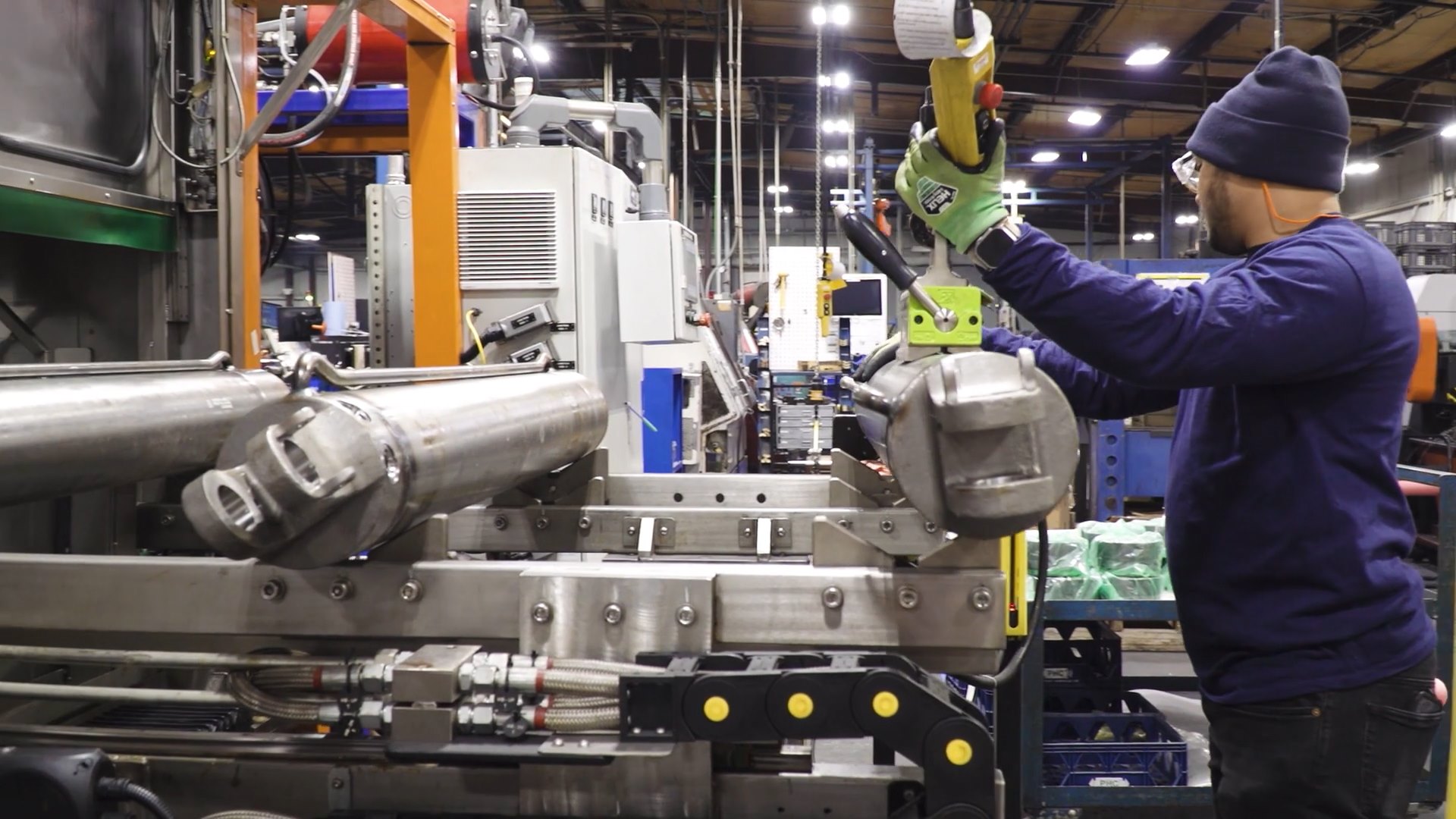

Precision’s advanced manufacturing plants are equipped with modern technology and automated testing systems. Our skilled teams focus on quality and efficiency, producing hydraulic cylinders that meet rigorous standards for customers around the world. With a global footprint and demonstrated capabilities, we’re ready to support your needs wherever you do business.